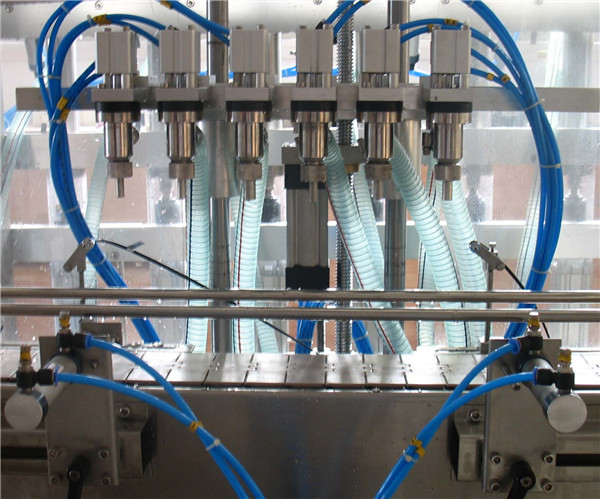

Automatic cream filling machine suitable for filling various viscosity, ranging from water thin liquids to thick creams.

The machine is automatic, inline piston filler that is designed to fill bottles and jars with products of various viscosity, ranging from water thin liquids to thick creams. They are used in the cosmetic, food, pharmaceutical, oil and specialty industries. These inline piston filling machines come complete with: two to twelve fill heads, a variable speed drive conveyor, adjustable heavy duty stainless steel frame, an easy to operate control panel.

304 Stainless steel heavy duty stainless steel welded C frame.

All contact parts are stainless steel, sanitary, Teflon, Viton and hoses per your requirements.

Real time adjustability.

No bottle no fill, PLC control

Accurate filling volume, within ±1% and a total bottle counter.

Easy to maintain, no special tools are required.

Special seals or hoses by order.

Blocked nozzles for products that tend to string and drip

Diving nozzles for bottom up filling of foaming products

Bottle mouth localizer.

The filling head can also be added to suit your special need...

Quick Details

Type: Filling Machine, Separating Plant

Application: Food, Beverage, Commodity, Medical, Chemical

Packaging Type: Cartons

Packaging Material: Wood

Automatic Grade: Automatic

Driven Type: Pneumatic

Voltage: 380V

Power: 4.5KW

Dimension(L*W*H): 500*400*1140

Weight: 80kg

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

Productivity: 1500-3000

Filling Speed: Adjustable

Filling Precisin: ≤±1%

Air Supply: 0.4-0.8MPa

Condition: New

Product Type: Perfume

Power(W): 4.5kw

Warranty: two years

| Nozzles | 6 nozzels. |

| Filling volume | 25-250ML 50-500ML 100-1000ML 500-2500ML |

| Filling speed | Adjustable according to different products. |

| Filling accuracy | Within ±1% |

| Voltage/ air pressure | 380V 50-60HZ 0.5-0.7MPA |

Main Features

1.Air Conveyor connectes with bottle-in starwheels. Bottle neck holding transferred.

2.Clamp transferring technology varied bottle types.

3.With little abrasion. Stable Transferring. Easy to change bottles.

4.With ring type pressure bearing hydraulic cylinder.

5.With high filling speed and exact liquid level.

6.Excellent Stainless Steel. Electric Components are of world known brand. All achieve national sanitary standard.

7.The bottle-out starwheel is of screwdown shape. No need to adjust transferring chain's height to different bottles. 8.Easy to operate and maintain.

9.PLC and transducers and othe main electric parts are of world famous brands, such as OMRON, MITSUBISHI etc.

Others

Lead time: within 30 working days

Warranty: Two year for whole machine, life time technical support

packaging: standard wooden case