1.The Scope of Application:

Labeling on front and back sides of different kinds objects with two labels at the same time.

(P.S. our labeling machine can be designed according to your needs)

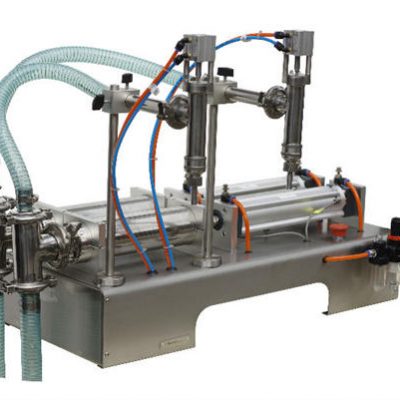

2. Device Characteristics:

Electrical cabinet,Conveying mechanism,Separate bottle device,Press bottle device,Roll label device,Brush label device,1# and

2# labeling engines,Operation system and control system

3. Device Advantages:

1) Control system: use Europe and United States series American AB brand PLC control system, with high stable operation and extremely low failure rate.

2) Operation system: The man-machine control 10 inch touch screen, directly visual interface easy operation ,with Chinese and English two kinds language, also rich with the help of the function and fault display function.

3) Check system:Use German LEUZE check label sensor, automatic check label station, stable and convenient don’t have much higher requirement for the worker.

4) Send label system:use American AB high-power servo control system, stable with high speed.

5) PARAMETER SAVE:can save 30 groups labeling parameters, when change the bottles, don’t need reset parameters, just adjust the machine part is ok.

6) Alarm function: such as label spill, label broken or other malfunction during machine working all will alarm and stop working.

7) Machine Material:The machine and spare parts all use material S304 stainless steel and anodized senior aluminum alloy,with high corrosion resistance and never rust.

8) Labeling way : use the servo send label system to send label on product surface.

9) Low voltage circuit all use the German Schneider brand.

Technical Parameter

Capacity (pcs/min) | 50-230 | Driving Mode | Servo motor |

Labeling Speed(m/min) | ≤35 | Label Specification | adhesive sticker,transparent or opaque |

The application of label object | diameter:12-24mm Height:25-95mm | The application of label | Height 20-70mm Length 25-80mm |

The inner diameter of label roll | 76mm(min) | The outer diameter of label roll | 350mm(max) |

No | Name | Model | Unit | Brand |

1 | PLC control system | 1763-L16BBB | 1 set | American AB |

2 | Touch-screen | TPC7062KW | 1piece | MGDS |

3 | Inverter | 22F-A2P5N103 | 1piece | Delta |

4 | photoelectric sensor (check bottle) | FS-N18N | 1Set | Japan KEYENCE |

5 | Photoelectric sensor (check label) | GS61 | 2sets | German Leuze |

6 | Main transport motor | 370W1:30 | 1piece | Switzerland ABB |

7 | Servo motor | 2004-RZ08BAIAN3 | 2 sets | America AB |

8 | Drive | 2003-CSD3-08BX2 | 2 sets | America AB |

9 | Separate Bottle Motor | 40W 1:30 | 2sets | German JSCC |

Quick Details

Type: Labeling Machine

Condition: New

Application: Beverage, Chemical, Commodity, Food, Machinery & Hardware, Medical

Packaging Type: Bottles

Packaging Material: Paper, Plastic

Automatic Grade: Automatic

Driven Type: Electric

Voltage: 220V,380V

Power: 1000W

Place of Origin: Shanghai, China (Mainland)

Brand Name: VKPAK

Dimension(L*W*H): 2400(L) 1350(W) 1500(H)mm

Weight: 280kg

Certification: ISO,CE

After-sales Service Provided: Engineers available to service machinery overseas

Drive mode: SERVO MOTOR

material: S304 Stainless Steel

character: labeling front and back sides

competitive edge: full set of siemens configuration

Labeling speed: 60-200pcs/min

Product name: Auto sticker Labeling Machine

Bottle type: Round Square Flat Pet Bottle

Function: Ahesive Sticker Labeling

Usage: Adhesive Labels Bottles

Advantage: Factory price Economy Labeling Machine