Cream Filling Machine

Creams are among the more viscous substances that our liquid filling machinery is capable of handling. For a selection of cream filling machines that can provide years of reliability in both efficiency and integrity, consider purchasing machinery from VKPAK. We offer a variety of liquid fillers, capping machines, labeling equipment, and conveyors. A facility utilizing a combination of this equipment can keep all liquid packaging processes consistently profitable.

Install a Complete Cream Filling Equipment System

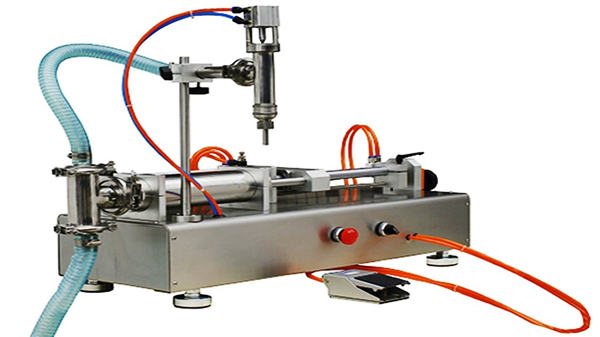

Our liquid filling equipment is designed to fill many different types of liquids, including creams of varying viscosity levels. Whether your cream product is thin or thick, we have machinery that can fill various types of containers, including gravity fillers, overflow fillers, and piston fillers. If you’re unsure which type of machines are suitable for your product, we can help you choose equipment based on viscosity and other factors.

After the liquid filling process, other types of liquid packaging machines we offer can complete other processes. We offer customizable cappers, conveyors, and labelers that can work cohesively to produce top-quality product packaging. Our team of experts can work with you to develop a solution that is compatible with your facility.

Configure a Custom Production Line

Like other types of liquid products, creams require production line configurations that work best with them specifically. Depending on the type of cream product and its packaging requirements, we can help you design and implement a customized liquid packaging line that gives your facility the results you want from liquid packaging processes. We offer size and setup options that can meet the individual requirements of your application, and assist with the implementation process.